|

Finished up the crash cymbal action. This one was an interesting design that I haven't seen up until this point. A double primary valve exists to fire the secondary. This is also the first time I experienced the self-tapping valves that Wurlitzer used in certain applications.

0 Comments

I had the opportunity to tour the shops of JL Weiler in Chicago. While there, I was introduced to the punch press, a machine that is used to punch holes in leather. In the case of an organ, there are many gaskets that need holes punched in certain places for screws to pass and wind channeling to function. Primary boxes contain three specialized gaskets with many varying sized holes in each. Although it is possible to punch these out by hand, a punch press greatly speeds things up. Arrangements were made to return with enough leather to punch 66 sets of primary box gaskets (198 total). Thank you Jeff Weiler and Mike Jacklin for making the photo below possible...!

For historical reference, the wood pictured below was had for a low price of only $778.93. About four times the cost as it was a year prior.

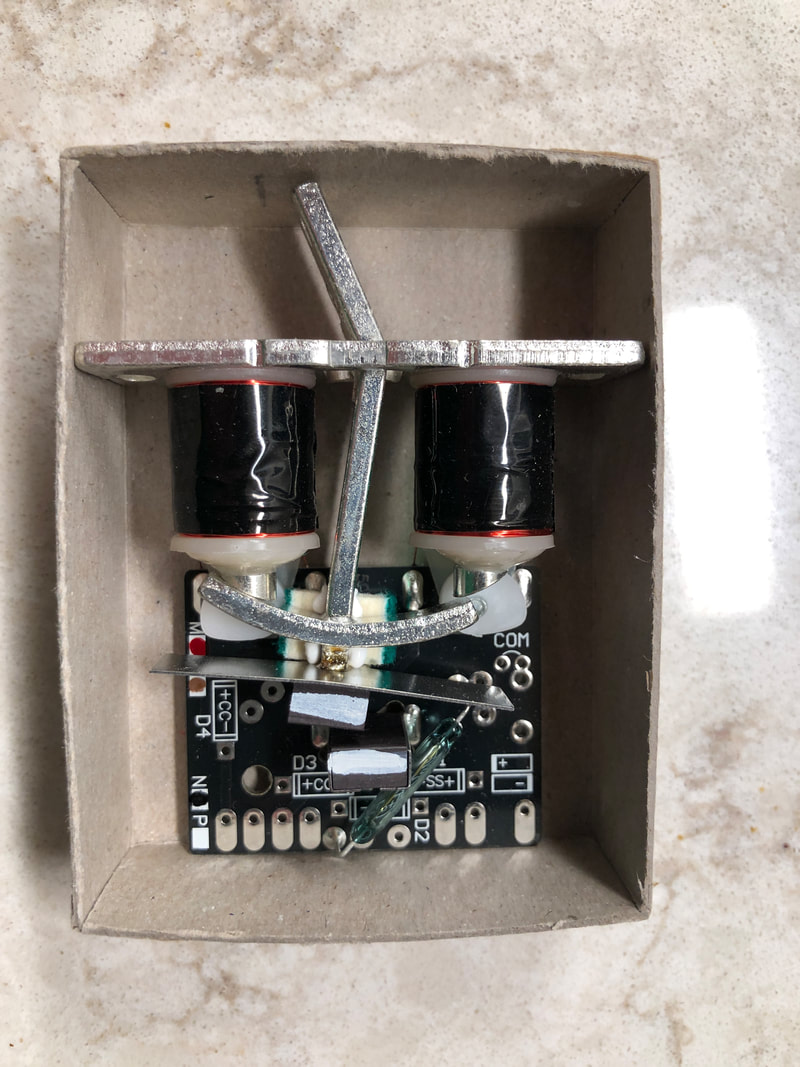

Due to COVID pandemic delays, the 10 replacement SAMs that were ordered back in November of 2020 finally arrived! They have been installed in the console to replace ones with burnt out coils. These are what the multi-colored stop tabs get mounted to. The coils with black foil around them are the magnets that move the switches up and down (on and off). The actual switch that tells the Uniflex relay that the stop is on or off is located towards the bottom of the board as the below image is oriented. It is called a reed switch and consists of two tiny pieces of metal that are moved together or apart based on magnetic fields produced by the magnets that are just above the switch.

|

The BlogCheck out this page for project updates! Archives

July 2024

Categories |

RSS Feed

RSS Feed