|

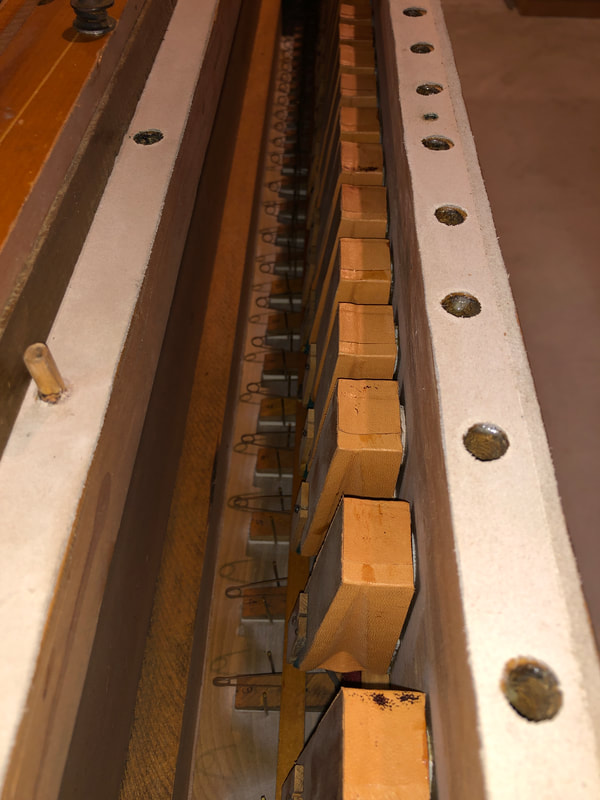

This past month, the chamber construction was completed with vinyl tile flooring going in and left over finished trim from the building of our house making a nice finish to the space. With the chamber finished, the Marimba was moved in since it is so large. Efforts have turned to wiring up all of the manual chests. At the time of writing this update, the single and seven rank chests are complete. Thanks goes out to my assistant, Eleanor for checking all 517 magnets with an ohm meter. Not bad for a four year old. Only seven dead magnets out of all of those, which were replaced with spares that I had on hand. Since the chests will need to be relatively close to the floor to fit pipework, reservoirs will need to go next to the chests and tremulants under the extra-wide walkboards. To aid in making repairs down the road, every bottom board is getting wired with a “pigtail” of 25-pair cable with a plug on the end. This way, I just need to unplug the specific bottom board that needs to be serviced, unscrew it and walk it over to the well-lit work bench!

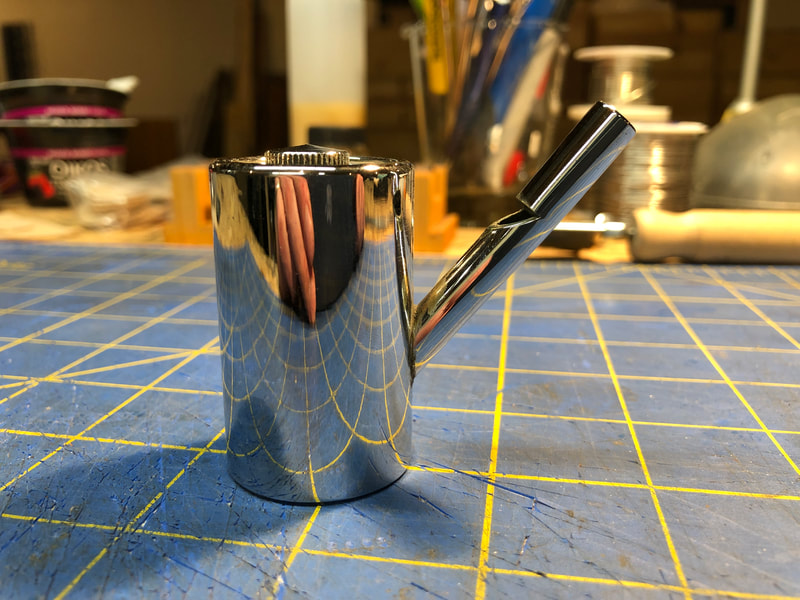

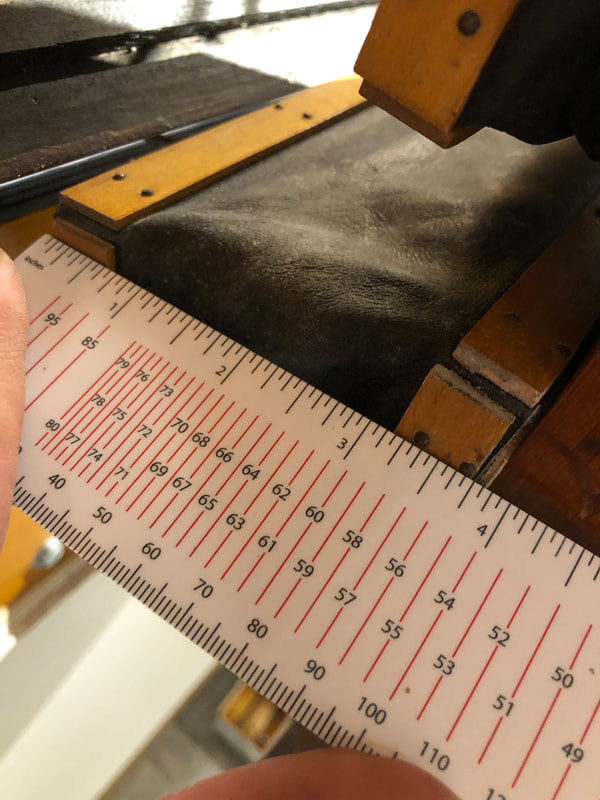

The other project that has been completed is the installation of both swell engines and re-leathering of the first stages of each power pneumatic. This was done with less leather than should be used to limit the travel of the first stage blades. The first stage only opens about an inch and the second stage opens about two inches. The slide whistle was also mounted in the tone chute with accordion pneumatic facing out for all to see who happens to be down there. It will be loud. I lucked out with the odd spacing of the studs due to the corner angled wall. The mounting holes on the whistle are 6.25” apart which hit the 2x4’s on center! Couldn’t have planned that better. Finally a word of thanks to my friend John Alford for sending me a Ludwig bird whistle! With some TLC, it shined up like a new penny. Thanks again John!

0 Comments

|

The BlogCheck out this page for project updates! Archives

July 2024

Categories |

RSS Feed

RSS Feed