|

This past month, the sleigh bells and glockenspiel were gone through, polished up and wired with plugs. As per all of the bottom boards, I am putting plugs on each piece in case something needs to be removed down the road for maintenance.

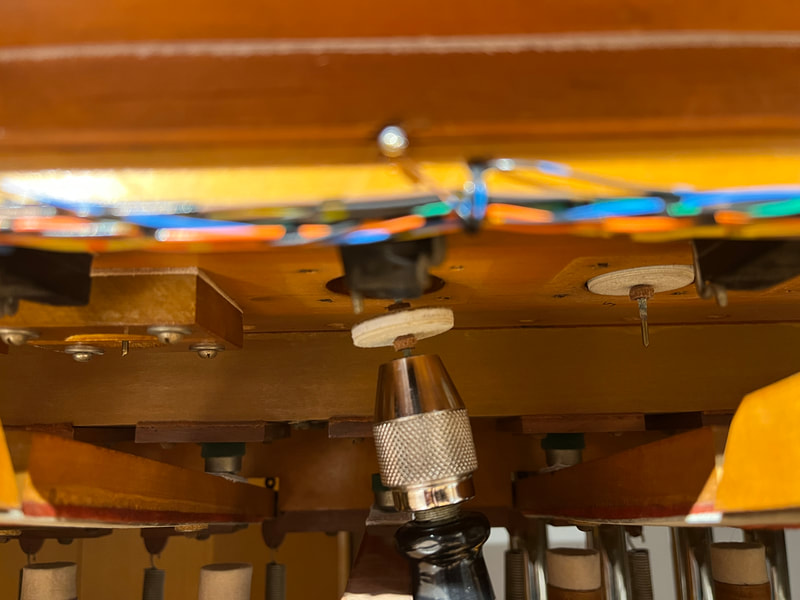

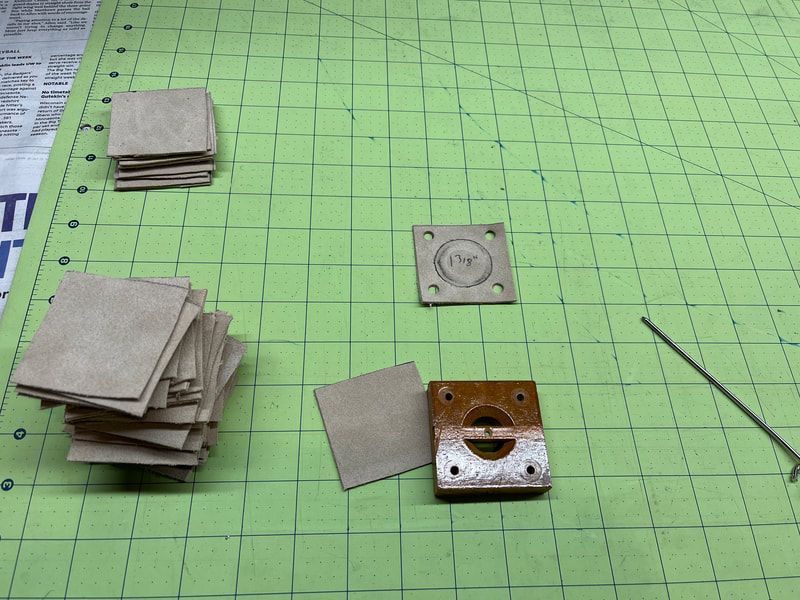

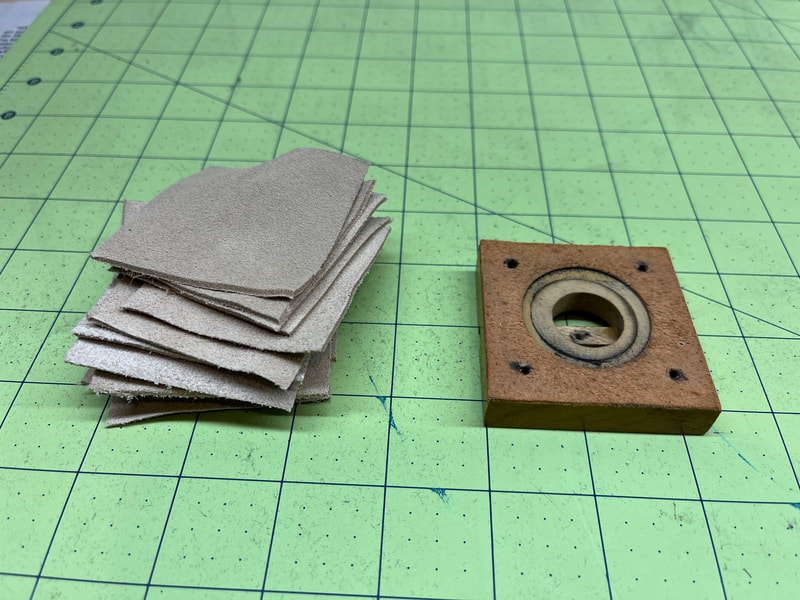

In preparation for connecting the tremulants to the manual chests, holes were drilled into the chests to exhaust wind into the trem manifolds that were built. One section of the manifold will connect the clarinet and diapason, while the other will connect the flute and three strings. In order to not damage any pneumatics, the bottom boards were dropped and holes started from the inside of the chest, then finished carefully from the outside. A thorough vacuuming finished the job in an attempt to prevent future ciphers. Perhaps the largest accomplishment was going through and regulating the marimba. Up until this point, it was mostly the way it was received when it came off the truck. Much was learned through doing this process. Most mallets came down sluggish, almost presenting a delay when playing it with other things. Some came down so slow that it didn’t actually touch the wood bar at all. Those were resolved by making adjustments to the valves. Another issue that was gone through was some notes that played but made more of a “thud” sound rather than reverberating. There are felt bumpers on set screws that can be adjusted that stop the mallets from traveling. The fix for those thud notes was to raise the stop bumpers so that the mallets stopped just shy of the bar. The spring steel allows for the mallet itself to travel just slightly past “stop”, striking the bar and then springing back so that the bar can reverberate. Another issue was the actions not returning quick enough. For this, there is a spring attached to the back of each hammer and a threaded rod with a wing nut on the bottom. Stretching the threaded rod down and adjusting the wing nut resolves those issues. Finally, and perhaps what makes me most happy… the marimba always sounded like a wind storm with many leaks. Although all of the internal leather components were redone nicely ahead of me getting the instrument, the valve gaskets were original 1928 leather. As soon as I realized that, all of the 49 covers came off and original gaskets were steamed off. New gaskets were cut and punched, then applied with fish glue. Lastly, all of the erecting lumber was spray shellacked with a mixture of amber shellac, die and denatured alcohol (cut about 50%). Eight coats with that mixture were applied to get a finish that is pretty close to some original Wurlitzer finished lumber. Ready for platform construction!

0 Comments

|

The BlogCheck out this page for project updates! Archives

July 2024

Categories |

RSS Feed

RSS Feed