|

This past month, work was completed to install the wall around the blowers. The ceiling joists were filled in with fiberglass insulation, four lights added and a smoke detector that is tied into the rest of the house system. If one goes off, they all go off! For an extra safe measure, there is also a fire extinguisher directly outside of the blower room. The door for the room is an exterior door that matches the ones used for the chamber and tone chute (sound insulating properties). This room is now ready for the drywallers (I have come to the conclusion that I am not good at drywall work).

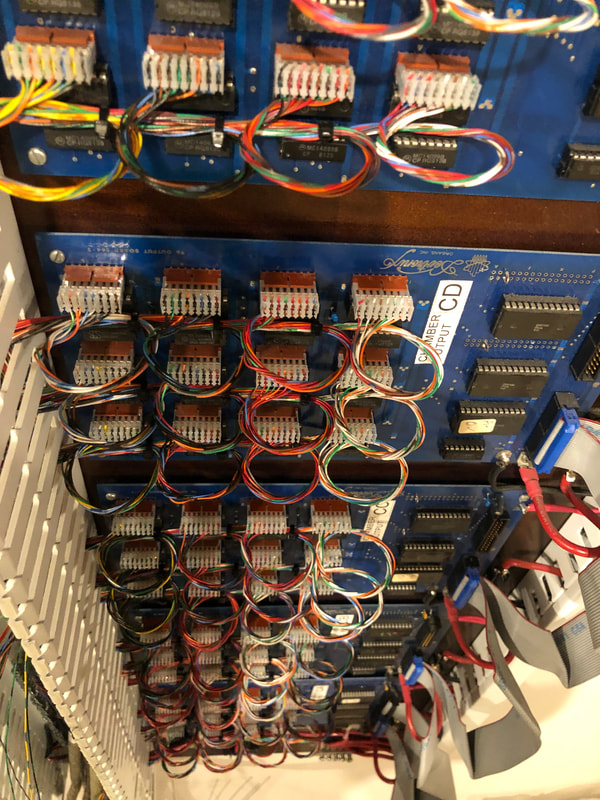

On the other side of the basement, more than half of the relay has been wired and offset chests have been placed in the locations they will live. In preparation for pipes, Ryan Mueller has taken the 15 that need to get mitered, which should be done soon. He also took the two 20x30 Wurlitzer reservoirs with him that needed to be rebuilt. One had a four-legged friend eat through a gusset and the other was missing outside corner pieces of leather. Although not directly connected to the organ, our in-floor heating system was installed this past week. At the time of building, tubing was installed in the entire concrete slab, minus the blower room. The organ has its own zone and thermostat to help keep it at a constant temperature. According to a document that Carlton Smith shared with me, the chamber should have a nominal temperature of 74 degrees and humidity should be between no less than 40% or higher than 50 %. The boiler is so quiet, I can barely hear it while standing next to it. If only the blowers were that quiet! Finally, Zach Frame stopped by and assisted in troubleshooting some console issues. A sticky key on the accompaniment no longer sticks, two pistons now are wired (never were wired to the input boards) and a very odd issue with a SAM that would now cancel now cancels. Turns out a blob of solder connected two of the output pins on the back of an output board. That one took a bit to find but an ohm meter helped track it down. There are only a couple of SAMs that have some issues with reed switches not canceling or being impacted in some way by neighboring SAMs (magnetic cross-talk). Sheet steel was purchased and little shields are being constructed to help block the cross-talk from occurring. More on that next month!

0 Comments

Leave a Reply. |

The BlogCheck out this page for project updates! Archives

July 2024

Categories |

RSS Feed

RSS Feed