|

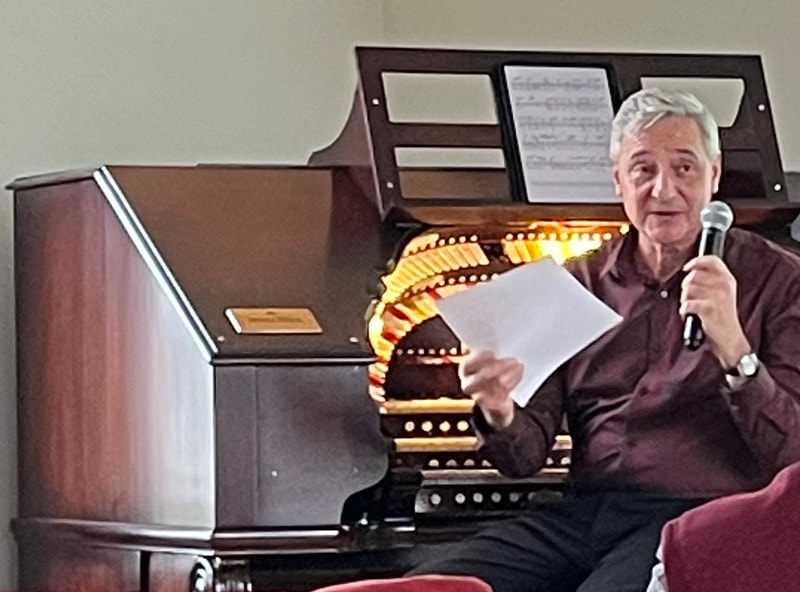

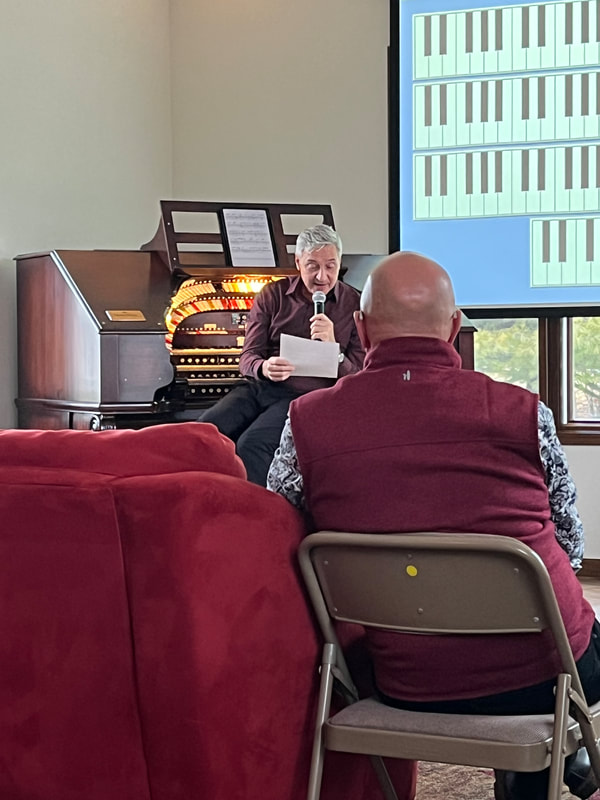

We were happy to welcome many friends, family and fellow DTOS members to our house on December 11th for a Christmas social, featuring Perry Petta. Perry played a 45-minute program followed by open console.

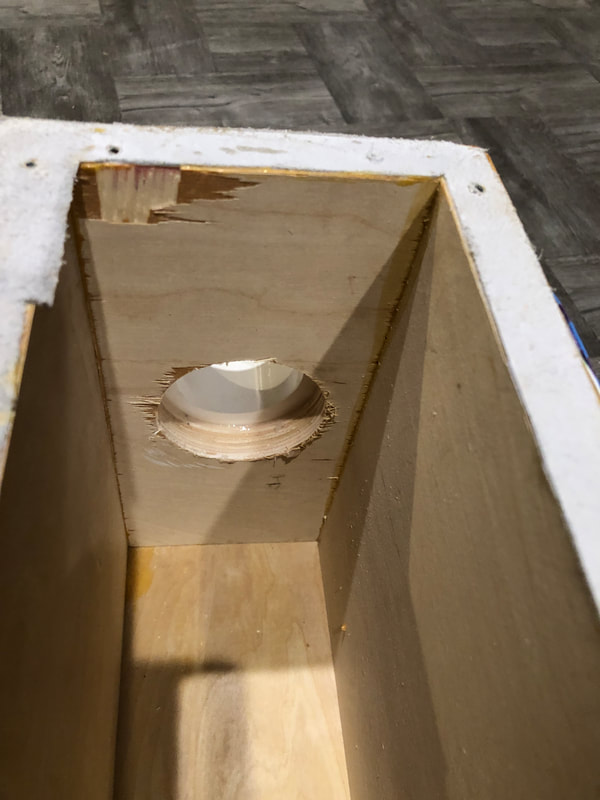

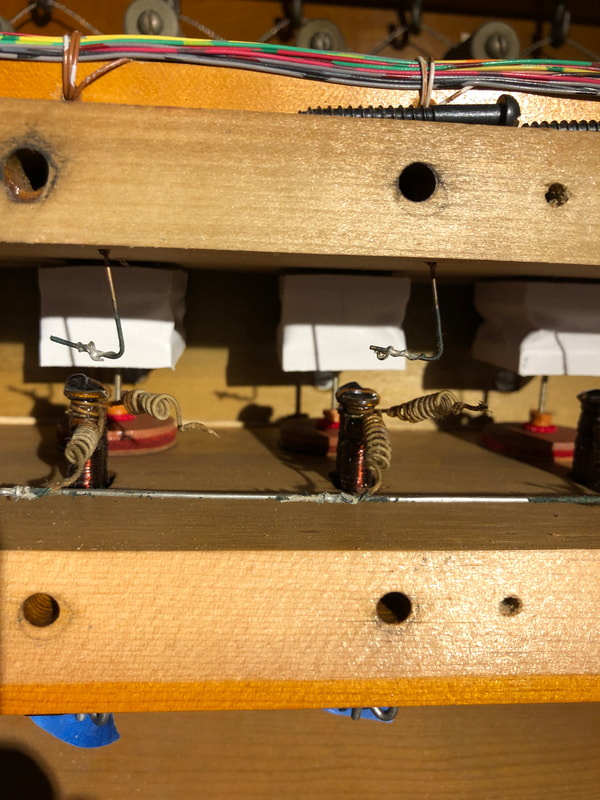

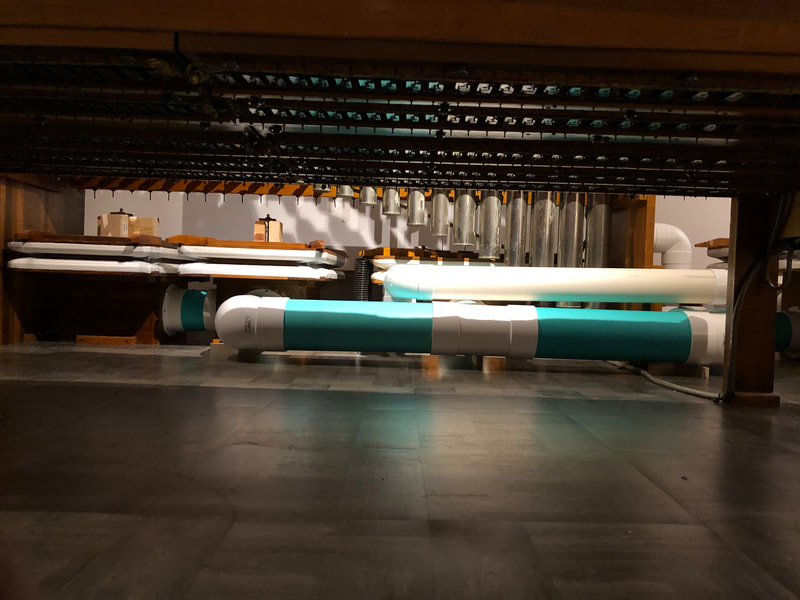

Much of this past month included cleaning things up in preparation for showing off progress made. Three more reservoirs were winded that all sit below the marimba harp. While Zach and I were at it, the marimba and chimes were winded (just in time for the social!). It took six springs and a lot of tweaking to get 15” of wind out of the reservoir, but it is working now! A six inch line comes off of the solo trunk and T’s off, feeding the 15” reservoir. The rest of the T continues on and 90s into the offset reservoir and from there goes straight into the post horn reservoir. Many notes needed to be adjusted on the Marimba and all needed to be adjusted on the chimes. What made the adjustment piece much easier was the help of the Uniflex remote tuner app. Individual notes could be commanded on or off from within the chamber. What a nice product! Although I am clear on how everything functions electrically, the winding piece of this assembly puzzle has allowed me to learn quite a bit about this particular “art”. Regulated pressure is achieved by adding spring tension / weights, which push down on the lid of the reservoir. The more tension, the more pressure. At first, you start with as little tension as possible, then slowly add by taking links of chain out. This is always done in pairs, kitty corner from each other. You never want to have one corner more than the rest. Always in pairs. The last little bit of progress downstairs involved the tuned bottles, which were tested and mounted in the tone chute. While on the bench, I replaced the LED tape that was originally installed so that the bottle lights could be a little more “warm”. The slide whistle also got releathered and a spring added for it to function properly as it is mounted. Upstairs, three more SAM shields were installed in the console after Perry rehearsed and found some stops that didn’t want to come on or cancel consistently. Those issues immediately went away post shield installation. Now I keep a few spare shields in a drawer just in case! A wireless microphone was also purchased to aid in hearing the organist speak. This worked out quite well for people that were around the corner from the music room. Finally, at the eleventh hour (Wednesday before the program), the baby grand piano developed a note that would stick down when played from the player system. Luckily, the installer who put the player system in could make it out the next day for an emergency repair. The issue was a tight flange in the back action. Later that night, the note acted up again, as well as another on the bass end of the piano. Friday consisted of a frantic day of calling around a dozen technicians in southeastern Wisconsin - quite possibly all of the technicians left in southeastern Wisconsin! One was able to make it out that evening and asked if after supper was okay. I said, “sure” we will be hosting a Christmas Vacation party and dressed up in character, but why not? In the middle of the party, he arrived and found the culprit. Dirt that had made its way into the cylinders where each player plunger rests under the keys. Pulling the plunger and vacuuming the dirt out is all it took!

0 Comments

Leave a Reply. |

The BlogCheck out this page for project updates! Archives

July 2024

Categories |

RSS Feed

RSS Feed