|

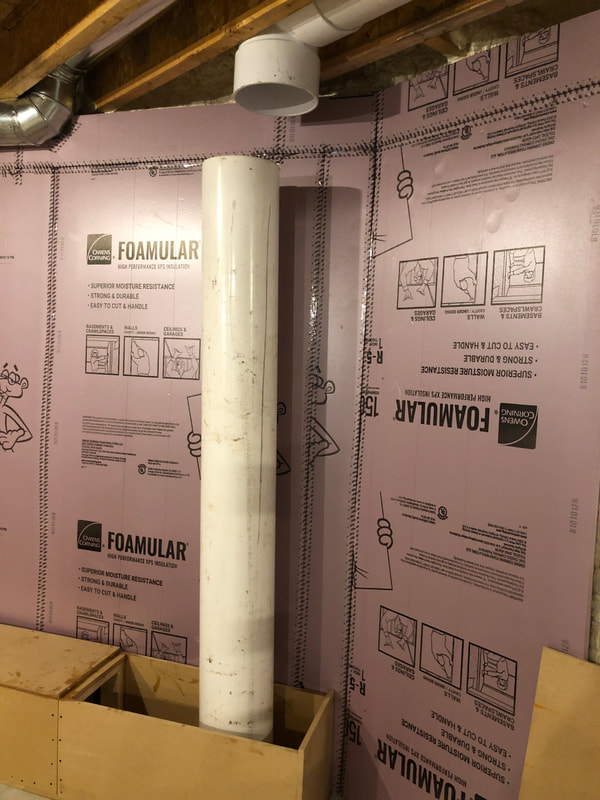

This past month, work has begun on mounting the rest of the static wind lines from the blower room. The lines now stretch from the blower room to the tone chute. The road block I ran into connecting the lines to the trunks that go into the chamber was the weight of the 10” lines from the ceiling to the trunks on the ground. I’d have to guess about 50 pounds per pipe just for that little section. Unistrut was purchased to provide mechanical support, so that the weight of the pipes aren’t solely supported by the PVC cement. Thanks to DTOS member, Steve Southworth for locating 10” unistrut pipe clamps on eBay. These are harder to find than you would think.

The 18 note chime action that I reported on last month has been completed and is awaiting installation in the tone chute after the drywall work is complete. Speaking of the tone chute, wall construction continued with the front wall going in. Special thanks to my neighbor John for helping me lift it in place and spending the following half hour with a sledge hammer getting the wall over the high spot in the floor. The dining room table above doesn’t lean too bad… That wall was wired up for lighting and outlets and is closer to being ready for drywall. Another challenge that was overcome was the wind line for the player piano which is going in the tone chute. The vacuum pump that I had was extremely noisy and smelt of ozone as soon as it was switched on. Not wanting to deal with the noise or potential fire from that unit, a new one was purchased and should arrive sometime in July. Depending on the noise level, the pump could probably just go in the bottom of the piano and not require a line from the blower room. Work has begun on a four-rank Wurlitzer chest which consists of a diapason, flute and two strings. As of the time of writing, the toe boards have been completely stripped of all pallets, pins and springs, leaving a flat surface on both sides. Next week, I will be taking them to Nolte’s shop in West Allis (which is too close for comfort to Grebe’s bakery). They have a sanding machine that will be used to ensure a flat surface for the pallets to seat on. Meanwhile, an A/V distribution system was put together to distribute sound and video to the projector and TVs. The idea is to have a camera feed of the music room to be viewed by people in the living room or downstairs who may not be able to see a performance. It can also be used for distributing video of a silent film if including that in a program.

0 Comments

Leave a Reply. |

The BlogCheck out this page for project updates! Archives

July 2024

Categories |

RSS Feed

RSS Feed